Tesla's Optimus Robot Program Faces Delays Due To China's Rare Earth Policy

Table of Contents

China's Dominance in Rare Earth Minerals and its Geopolitical Implications

China holds a near-monopoly on the mining and processing of rare earth elements (REEs), a group of 17 minerals crucial for numerous high-tech applications. These minerals are not rare in the geological sense, but their extraction and refinement are complex and energy-intensive processes, giving China a significant competitive advantage. This dominance has far-reaching geopolitical implications, as REEs are essential components in various technologies, including electric vehicles, smartphones, wind turbines, and, critically, robotics. China's control over the supply chain allows it to exert considerable influence on global markets and international relations.

- Specific rare earth elements crucial for Optimus robots: Neodymium and dysprosium are particularly important for the powerful, yet compact, motors needed in Optimus's actuators and locomotion systems.

- Percentage of global rare earth production controlled by China: China controls over 60% of global rare earth production, effectively dominating the market.

- Examples of other tech industries affected by China's rare earth policy: The electric vehicle industry, particularly manufacturers reliant on permanent magnet motors, is similarly vulnerable to supply chain disruptions.

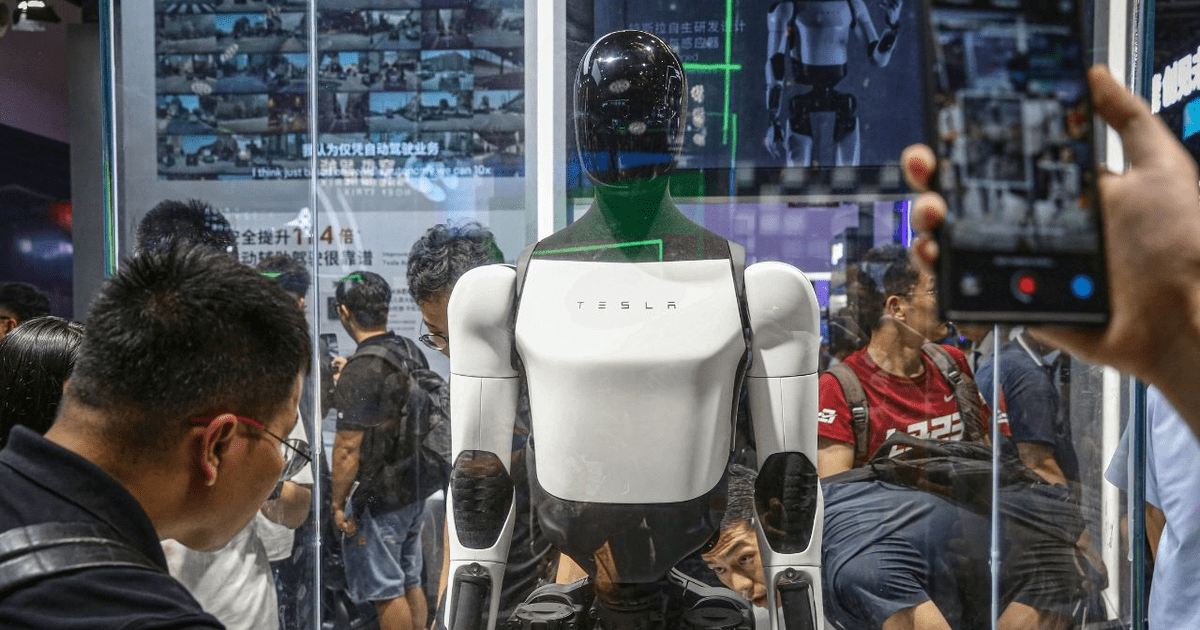

The Impact on Tesla's Optimus Robot Production Timeline

The reliance of Optimus robots on rare earth minerals directly translates to significant vulnerabilities in Tesla's production chain. Several key components, such as the motors mentioned above, rely heavily on these minerals. Any disruption in the supply of these materials, whether due to price fluctuations or geopolitical tensions, can lead to significant delays in production schedules and increased manufacturing costs. This could delay Optimus's planned rollout and market entry, potentially impacting Tesla's ambitious timeline.

- Specific robot parts affected by rare earth shortages: Actuators, motors, and sensors are particularly susceptible to supply chain interruptions.

- Estimated cost increases due to rare earth mineral price fluctuations: Price volatility in rare earth minerals can significantly impact the overall manufacturing cost of Optimus robots, potentially affecting profitability.

- Revised launch dates (if any) for Optimus robots: While official launch dates remain fluid, any delays caused by rare earth supply chain issues could push back the market entry of Optimus robots.

Tesla's Potential Strategies to Mitigate Rare Earth Dependency

To mitigate the risks associated with its reliance on Chinese rare earth minerals, Tesla needs to adopt a multi-pronged strategy. This could involve diversifying its sourcing of rare earths, exploring alternative materials, or investing in its own rare earth mining and processing capabilities.

- Potential sources for rare earth minerals: Australia, the United States, and some countries in Africa possess significant rare earth reserves, offering potential alternative sourcing options.

- Research into rare-earth-free motor designs: Investing in R&D for alternative motor designs that minimize or eliminate the need for rare earth magnets is crucial for long-term independence.

- Potential partnerships with mining companies or other technology firms: Strategic alliances can help Tesla secure access to stable and reliable rare earth supplies.

The Broader Implications for the Robotics Industry

China's dominance in rare earth minerals has implications that extend far beyond Tesla's Optimus program. The entire global robotics industry faces the risk of supply chain disruptions and price volatility, potentially hindering innovation and slowing down the overall development of robotics technology. This could lead to increased geopolitical tensions and trade disputes, further complicating the already complex global supply chain.

- Examples of other robotics companies impacted by rare earth supply issues: Many robotics companies, both large and small, rely on similar components and are thus equally vulnerable to disruptions.

- Potential for increased research and development into alternative materials: The current situation incentivizes increased investment in R&D for alternative materials and sustainable manufacturing practices.

- Long-term shifts in the global robotics manufacturing landscape: The current dependency could drive a reshaping of the global robotics manufacturing landscape, with companies seeking diversification and regionalization of their supply chains.

Conclusion: Navigating the Future of Tesla's Optimus Robot Program

Tesla's Optimus robot program faces considerable challenges due to China's control over the rare earth mineral market. This dependence impacts production timelines, increases costs, and introduces geopolitical risks. Diversifying rare earth sourcing and investing in alternative materials are crucial for the long-term success of the Optimus program and the broader robotics industry. Staying informed about developments in alternative materials, sustainable robotics practices, and the evolving geopolitical landscape surrounding rare earth minerals is vital to understanding the future of Tesla's Optimus Robot Program and the broader technological landscape. Follow the developments in this crucial area to stay ahead of the curve.

Featured Posts

-

The Value Of Middle Managers Benefits For Companies And Employees

Apr 24, 2025

The Value Of Middle Managers Benefits For Companies And Employees

Apr 24, 2025 -

The Bold And The Beautiful April 9th Recap Steffys Anger And Liams Plea For Secrecy

Apr 24, 2025

The Bold And The Beautiful April 9th Recap Steffys Anger And Liams Plea For Secrecy

Apr 24, 2025 -

The Danger Of Missed Mammograms Learning From Tina Knowles Diagnosis

Apr 24, 2025

The Danger Of Missed Mammograms Learning From Tina Knowles Diagnosis

Apr 24, 2025 -

South Carolina Voter Confronts Rep Nancy Mace A Heated Exchange

Apr 24, 2025

South Carolina Voter Confronts Rep Nancy Mace A Heated Exchange

Apr 24, 2025 -

Tzin Xakman O Tzon Travolta Apoxaireta Ton Thryliko Ithopoio

Apr 24, 2025

Tzin Xakman O Tzon Travolta Apoxaireta Ton Thryliko Ithopoio

Apr 24, 2025