Robots Vs. Sneakers: The Manufacturing Hurdles

Table of Contents

The Complexity of Sneaker Construction

Sneaker manufacturing is far more intricate than it might initially seem. The seemingly simple shoe is a marvel of engineering, requiring precision and skill at every stage of production. Let's break down some of the key complexities:

Material Diversity

Sneakers utilize a vast array of materials – from premium leather and supple suede to durable synthetics, flexible mesh, and resilient rubber outsoles. Each material possesses unique properties requiring specialized handling and processing.

- Challenges: Adapting robotic systems to consistently handle the diverse textures, thicknesses, and sensitivities of these materials is a major hurdle. Robotic grippers need to be sufficiently robust to avoid damaging delicate materials while also possessing the dexterity to manipulate more rigid components.

- Solutions: The development of advanced sensor technology and adaptable robotic grippers is crucial. Force feedback sensors allow robots to adjust their grip pressure according to the material, preventing damage. Computer vision systems can identify and categorize materials, enabling robots to select appropriate handling techniques.

Precise Assembly

The assembly process itself is incredibly complex, involving precise stitching, gluing, and layering of multiple components. This requires a high degree of accuracy and dexterity, traditionally performed by skilled human workers.

- Challenges: Replicating the fine motor skills of human workers with robotic precision is a significant technical challenge. The intricate nature of sneaker construction presents a difficulty for robotic programming and execution.

- Solutions: Investing in advanced robotic arms with force feedback and sophisticated vision systems is crucial. These systems enable robots to monitor the assembly process in real-time, ensuring accuracy and identifying any defects.

Customization and Personalization

The increasing demand for customized sneakers, with personalized designs and unique features, presents a new manufacturing challenge. Mass production methods struggle to accommodate individual preferences efficiently.

- Challenges: Scaling robotic systems to accommodate individualized designs and orders efficiently while maintaining cost-effectiveness is a considerable hurdle. Flexibility is key here.

- Solutions: Implementing flexible automation systems and integrating 3D printing technologies are key to meeting this challenge. 3D printing allows for the creation of bespoke components, while flexible automation systems can adapt to varying production requirements.

The Economic Considerations of Automation

While robotic automation offers potential benefits, it's crucial to consider the economic implications. The initial investment and long-term cost-effectiveness are critical factors.

High Initial Investment Costs

Implementing robotic systems in sneaker manufacturing requires a significant upfront investment in advanced hardware, sophisticated software, and skilled technicians for integration and maintenance.

- Challenges: High capital expenditure can be a barrier for smaller manufacturers, potentially creating an uneven playing field.

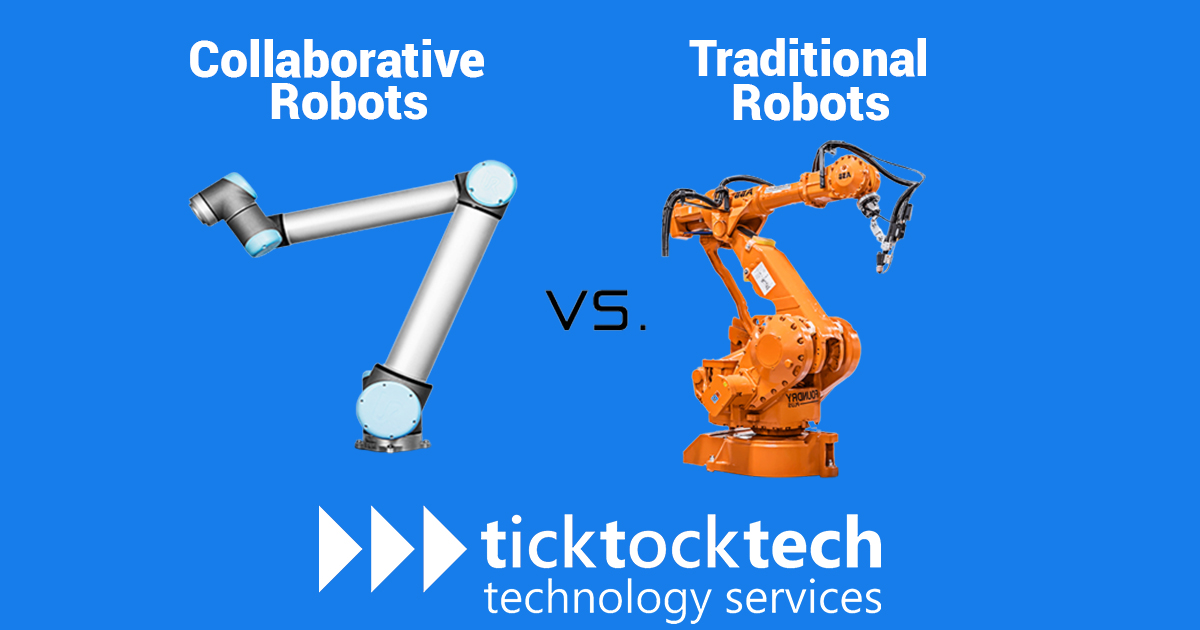

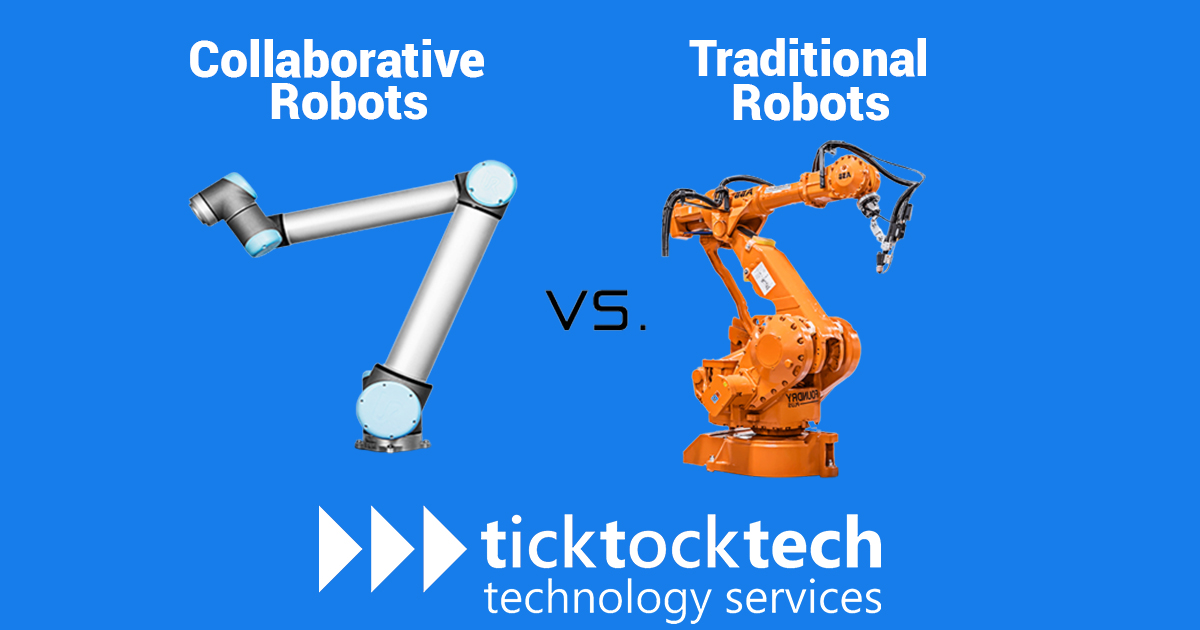

- Solutions: Exploring leasing options, seeking government subsidies specifically designed for automation upgrades, and adopting collaborative robot (cobot) solutions – which are often more affordable – can help mitigate these costs.

Return on Investment (ROI)

The return on investment for robotic automation depends heavily on production volume and efficiency gains. A thorough analysis is vital to ensure profitability.

- Challenges: Determining the break-even point and ensuring a sufficient return on investment requires careful planning and accurate forecasting.

- Solutions: Conducting thorough cost-benefit analyses before implementation, focusing automation efforts on high-volume production lines initially, and exploring automation selectively, starting with processes that offer the greatest potential for efficiency gains, is crucial.

Job Displacement Concerns

The introduction of automation raises concerns about potential job displacement for human workers involved in traditional manufacturing roles.

- Challenges: Addressing worker retraining needs and mitigating the social and economic impacts of job displacement is crucial for responsible automation implementation.

- Solutions: Focusing on collaborative robotics, where humans and robots work together, leveraging human expertise for complex tasks, and investing in extensive workforce reskilling programs is essential.

The Ongoing Role of Human Labor

Despite the rise of automation, human labor remains vital in many aspects of sneaker manufacturing. Human skills and judgment still play irreplaceable roles.

Intricate Tasks Requiring Human Skill

Certain aspects of sneaker production, such as intricate hand-stitching, particularly on high-end footwear, or detailed quality inspection, require the fine motor skills and judgment that currently surpass robotic capabilities.

- Challenges: Finding and retaining skilled workers in a competitive labor market is a significant challenge for manufacturers.

- Solutions: Investing in apprenticeship programs, offering competitive wages and benefits packages, and creating a positive and supportive work environment are key strategies for attracting and retaining skilled workers.

Quality Control and Inspection

Human inspectors remain crucial for detecting subtle defects that even advanced automated vision systems might miss. The human eye often possesses superior discernment for quality assessment.

- Challenges: Maintaining consistent quality control standards across different production lines and ensuring consistent training and standards for human inspectors is key.

- Solutions: Combining human inspection with automated vision systems creates a comprehensive quality assurance strategy, leveraging the strengths of both human expertise and automated precision.

The Value of Craftsmanship

Many consumers value the craftsmanship and attention to detail associated with hand-made or hand-finished sneakers. This demand highlights the enduring importance of human skill in the industry.

- Challenges: Balancing automation with the demand for handcrafted elements and maintaining the perceived value of human-crafted products requires careful consideration.

- Solutions: Exploring hybrid manufacturing models, combining robotic efficiency for high-volume production with human skill and artistry for specialized or limited-edition products, is a viable strategy.

Conclusion

The integration of robots into sneaker manufacturing presents both exciting opportunities and significant challenges. While automation offers the potential for increased efficiency, reduced costs, and greater customization, the complexity of sneaker construction, the economic considerations, and the ongoing need for human expertise must all be carefully considered. The future likely lies in a collaborative approach, where robots and humans work together to optimize the production process, deliver high-quality footwear, and meet the evolving demands of the market. To stay ahead of the curve, manufacturers need to carefully evaluate the benefits and drawbacks of robotic automation and develop strategies to integrate this technology effectively. Embrace the future of sneaker manufacturing by understanding the crucial role of robots and humans in this dynamic landscape. Learn more about optimizing your sneaker production with effective robotic integration.

Featured Posts

-

Fbi Probes Multi Million Dollar Office365 Data Breach Targeting Executives

Apr 22, 2025

Fbi Probes Multi Million Dollar Office365 Data Breach Targeting Executives

Apr 22, 2025 -

The Blue Origin Debacle Is Jeff Bezos Failure Larger Than Katy Perrys Recent Challenges

Apr 22, 2025

The Blue Origin Debacle Is Jeff Bezos Failure Larger Than Katy Perrys Recent Challenges

Apr 22, 2025 -

Alterya Acquired By Blockchain Security Firm Chainalysis

Apr 22, 2025

Alterya Acquired By Blockchain Security Firm Chainalysis

Apr 22, 2025 -

Putin Ends Easter Truce Ukraine Conflict Intensifies

Apr 22, 2025

Putin Ends Easter Truce Ukraine Conflict Intensifies

Apr 22, 2025 -

Betting On Natural Disasters The Los Angeles Wildfires And The Changing Landscape Of Gambling

Apr 22, 2025

Betting On Natural Disasters The Los Angeles Wildfires And The Changing Landscape Of Gambling

Apr 22, 2025