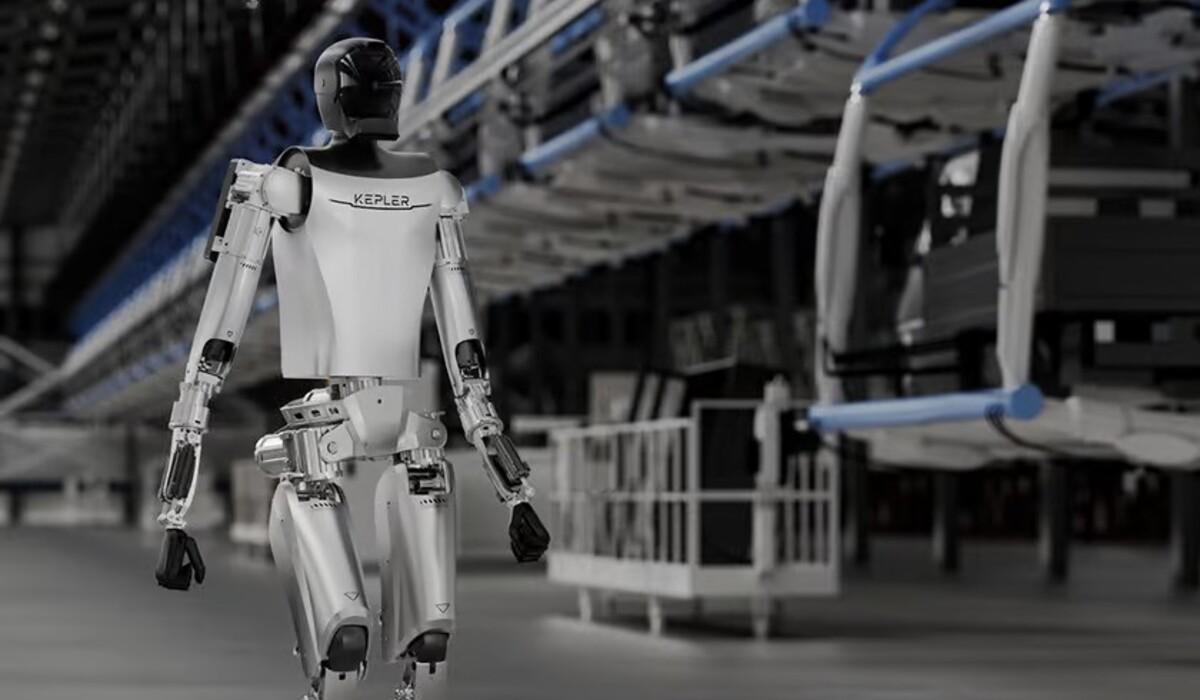

Rare Earth Supply Chain Issues Hamper Tesla's Optimus Humanoid Robot Development

Table of Contents

The Critical Role of Rare Earth Elements in Robotics

Rare earth elements (REEs) are vital components in many high-tech applications, and humanoid robots are no exception. Their unique magnetic and electronic properties make them indispensable for several key functions within the Tesla Optimus.

Rare Earth Elements in Optimus's Motors and Actuators

The motors and actuators that power the movement and precision of the Tesla Optimus heavily rely on rare earth elements like neodymium and dysprosium. These elements are crucial for creating powerful and compact permanent magnets necessary for efficient motor operation. Substituting them with readily available alternatives is challenging, as no other elements offer the same combination of strength, temperature resistance, and cost-effectiveness.

- Neodymium magnets: Provide high magnetic strength for powerful motor torque.

- Dysprosium magnets: Enhance temperature resistance, crucial for preventing performance degradation under high operational loads.

- Other REEs: Samarium and praseodymium are also used in smaller quantities for various components.

The precise control and power needed for a sophisticated humanoid robot like Optimus depend heavily on these high-performance magnets. Finding suitable replacements would drastically alter the robot's design, functionality, and cost-effectiveness.

Challenges in Sourcing and Refining Rare Earth Minerals

The global distribution of rare earth minerals is highly concentrated, primarily in China. This geographical concentration creates geopolitical complexities and risks for companies like Tesla that rely on these elements. The mining and refining processes are also environmentally intensive, raising concerns about sustainability and ethical sourcing.

- Geopolitical risks: Dependence on a single major supplier increases vulnerability to political instability and trade disputes.

- Environmental concerns: REE mining and refining generate significant waste and pollution, requiring stringent environmental regulations.

- Ethical sourcing: Ensuring responsible mining practices and fair labor standards throughout the supply chain is paramount.

China currently dominates the global rare earth market, controlling a significant portion of mining, processing, and refining. This concentration presents a considerable risk for companies like Tesla, making securing a consistent and ethical supply a significant challenge. According to a recent USGS report, China accounts for over 70% of global rare earth production. This dominance necessitates careful planning and diversification strategies for companies like Tesla.

Impact of Supply Chain Disruptions on Optimus Production Timeline

The precariousness of the rare earth supply chain significantly impacts Tesla's ability to deliver the Optimus humanoid robot on schedule and within budget.

Delays and Cost Increases Due to Rare Earth Shortages

Shortages or disruptions in the rare earth supply chain can cause considerable delays in Optimus's development and production. The increased cost of securing these materials also impacts Tesla's profitability and the overall price of the robot. This can lead to ripple effects throughout the manufacturing process, delaying other related projects and impacting Tesla's overall financial performance.

- Potential delays: Experts predict significant delays, potentially pushing back the mass production of Optimus by several years.

- Increased costs: Fluctuations in REE prices can drastically impact the manufacturing cost of Optimus, potentially making it less competitive.

- Ripple effects: Delays in Optimus production can also impact the development of related technologies and Tesla's broader automation strategy.

Tesla's Strategies to Mitigate Supply Chain Risks

Tesla is likely exploring various strategies to mitigate the risks associated with rare earth dependency. This might involve vertical integration (controlling more stages of the supply chain), research into alternative materials that can replace or reduce the need for REEs, and diversifying its suppliers to reduce reliance on any single source.

- Vertical integration: Investing in rare earth mining and processing operations to secure a more stable supply.

- Alternative materials: Researching and developing alternative materials and technologies that minimize or eliminate the need for REEs.

- Supplier diversification: Partnering with multiple suppliers across different geographical regions to reduce reliance on a single source.

However, each of these strategies presents its own set of challenges and complexities. Vertical integration requires significant capital investment and expertise, while finding suitable alternative materials and establishing reliable partnerships with new suppliers can prove time-consuming and complex.

The Broader Implications for the Humanoid Robotics Industry

The challenges faced by Tesla with rare earth supply chain issues are not unique. The entire humanoid robotics industry faces similar vulnerabilities.

Challenges for Other Robotics Companies Facing Similar Issues

Many companies developing humanoid robots face similar hurdles regarding rare earth element sourcing. This scarcity and supply chain instability pose significant challenges to the growth and competitiveness of this emerging industry. The cost and availability of REEs are crucial factors influencing the development timelines, production scales, and overall market viability of humanoid robots.

The Need for Sustainable and Ethical Sourcing of Rare Earth Elements

The long-term sustainability and ethical considerations of rare earth mining are critical. Developing sustainable and ethically sourced rare earth materials is crucial not only for the humanoid robotics industry but also for a wide range of high-tech applications. This necessitates technological innovation to reduce reliance on these elements and promote responsible mining practices.

Conclusion: Addressing Rare Earth Supply Chain Issues for Future Optimus Development

The successful development and widespread adoption of Tesla's Optimus humanoid robot, and indeed the entire humanoid robotics industry, are critically dependent on addressing the challenges posed by rare earth supply chain issues. The reliance on rare earth elements for essential components like motors and actuators presents significant risks, including potential delays, increased costs, and geopolitical vulnerabilities. Tesla and other companies in the sector need to actively pursue sustainable sourcing, explore alternative materials, and diversify their supply chains to ensure the future of this exciting technology. The future of humanoid robotics, including Tesla's Optimus, depends heavily on addressing rare earth supply chain issues. Stay informed about developments in sustainable sourcing and technological innovation to understand the evolution of this critical sector.

Featured Posts

-

Saudi India Oil Refinery Partnership A Boost For Energy Security

Apr 24, 2025

Saudi India Oil Refinery Partnership A Boost For Energy Security

Apr 24, 2025 -

Cybercriminals Office365 Hack Results In Millions In Losses Fbi Confirms

Apr 24, 2025

Cybercriminals Office365 Hack Results In Millions In Losses Fbi Confirms

Apr 24, 2025 -

Klaus Schwab Under Scrutiny World Economic Forum Faces New Investigation

Apr 24, 2025

Klaus Schwab Under Scrutiny World Economic Forum Faces New Investigation

Apr 24, 2025 -

Google Fis 35 Unlimited Plan Is It Right For You

Apr 24, 2025

Google Fis 35 Unlimited Plan Is It Right For You

Apr 24, 2025 -

77 Inch Lg C3 Oled Is It Worth The Investment My Honest Review

Apr 24, 2025

77 Inch Lg C3 Oled Is It Worth The Investment My Honest Review

Apr 24, 2025