Exploring Pentrich Brewing: Inside The Factory

Table of Contents

The Brewing Process at Pentrich Brewing

From Grain to Glass: A Step-by-Step Guide

The journey of a Pentrich Brewing beer begins with carefully selected grains. The malting process, a crucial first step, transforms barley into malt, providing the foundation for our distinctive brews. This is followed by mashing, where the malt is mixed with hot water to release the sugars. The resulting liquid, called wort, then undergoes lautering, a process that separates the sweet wort from the spent grain.

Next comes the boiling stage, where hops are added to impart bitterness, aroma, and flavour. At Pentrich, we pride ourselves on our hop selection, sourcing premium varieties from around the world. The specific hops used vary depending on the beer style, resulting in a unique flavour profile for each brew. After boiling, the wort is cooled and transferred to fermentation tanks where carefully chosen yeast strains are introduced. This fermentation process transforms the sugars into alcohol and carbon dioxide, giving the beer its character. Finally, after conditioning, the beer is ready for packaging, carefully bottled or canned and prepared for distribution.

- Key Ingredients:

- Maris Otter Malt (UK)

- Fuggles Hops (UK)

- East Kent Goldings Hops (UK)

- Wyeast 1056 American Ale Yeast

- (Specific ingredients will vary depending on the beer style)

[Include high-quality images or videos of each stage here]

Quality Control and Assurance at Pentrich

At Pentrich Brewing, quality is paramount. We employ rigorous quality control and quality assurance measures throughout the entire brewing process. From the initial grain inspection to the final taste test, every step is meticulously monitored. Our commitment to excellence is reflected in our adherence to the highest brewing standards.

- Specific Quality Checks:

- Regular sensory evaluations (taste tests) by our expert panel.

- Microscopic examination of yeast and bacterial cultures.

- Chemical analysis to ensure consistent alcohol content and pH levels.

- Comprehensive sanitation protocols to prevent contamination.

We are proud to have received [mention any relevant certifications or awards, e.g., a Great British Beer Festival award]. This commitment to maintaining consistently high standards ensures every bottle of Pentrich Brewing beer delivers an exceptional experience.

The People Behind Pentrich Brewing

Meet the Brewmaster and Team

Behind every great beer is a passionate team. Meet our brewmaster, [Brewmaster's Name], a veteran with [number] years of experience in crafting exceptional ales. [Include a short biography and engaging quote from the brewmaster]. Our dedicated team also includes [mention key personnel and their roles, including short bios].

[Include photos of the team here]

The Pentrich Brewing Culture

At Pentrich Brewing, we foster a collaborative and innovative company culture. We are committed to sustainability, minimizing our environmental footprint through responsible sourcing and waste reduction initiatives. We also believe in strong community involvement, supporting local charities and events.

-

Sustainability Initiatives:

- Use of renewable energy sources where possible.

- Water conservation measures.

- Recycling and waste reduction programs.

-

Community Involvement:

- Sponsorship of local sports teams.

- Participation in community festivals.

- Donations to local charities.

The Pentrich Brewing Factory Tour

A Glimpse into the Production Facility

Our state-of-the-art production facility is a sight to behold. A brewery tour would reveal the impressive array of brewing equipment and cutting-edge brewing technology used to produce our beers. From the massive stainless steel fermentation tanks to the high-speed bottling line, every aspect of the facility reflects our commitment to efficiency and quality.

[Include stunning photos of the factory's interior here]

- Unique aspects of the facility: [mention any unique features, e.g., a specific type of mash tun, innovative filtration system].

The Packaging and Distribution Process

Once the brewing process is complete, the beer moves to the packaging stage. At Pentrich, we offer our beers in [mention packaging types, e.g., bottles and cans]. Our efficient distribution network ensures our beers reach pubs, bars, and shops across [mention region].

[Include photos of the packaging process here]

Conclusion

Pentrich Brewing represents a commitment to quality, craftsmanship, and community. From the meticulous brewing process to the passionate team behind the brand, every aspect reflects a dedication to producing exceptional beers. The scale of our operation and the cutting-edge technology in our factory are a testament to our commitment to consistently high-quality products.

Explore Pentrich Brewing further by visiting their website, seeking out their products at your local retailer, or, if offered, taking a tour of their impressive factory. Discover the amazing world of Pentrich Brewing – a leader in the Derbyshire craft beer scene. Learn more about Pentrich Brewing today!

Featured Posts

-

How Netflix Is Weathering The Big Tech Storm And Attracting Tariff Seeking Investors

Apr 23, 2025

How Netflix Is Weathering The Big Tech Storm And Attracting Tariff Seeking Investors

Apr 23, 2025 -

Yankees Record Breaking Night Judges 3 Home Runs Lead To 9 Total

Apr 23, 2025

Yankees Record Breaking Night Judges 3 Home Runs Lead To 9 Total

Apr 23, 2025 -

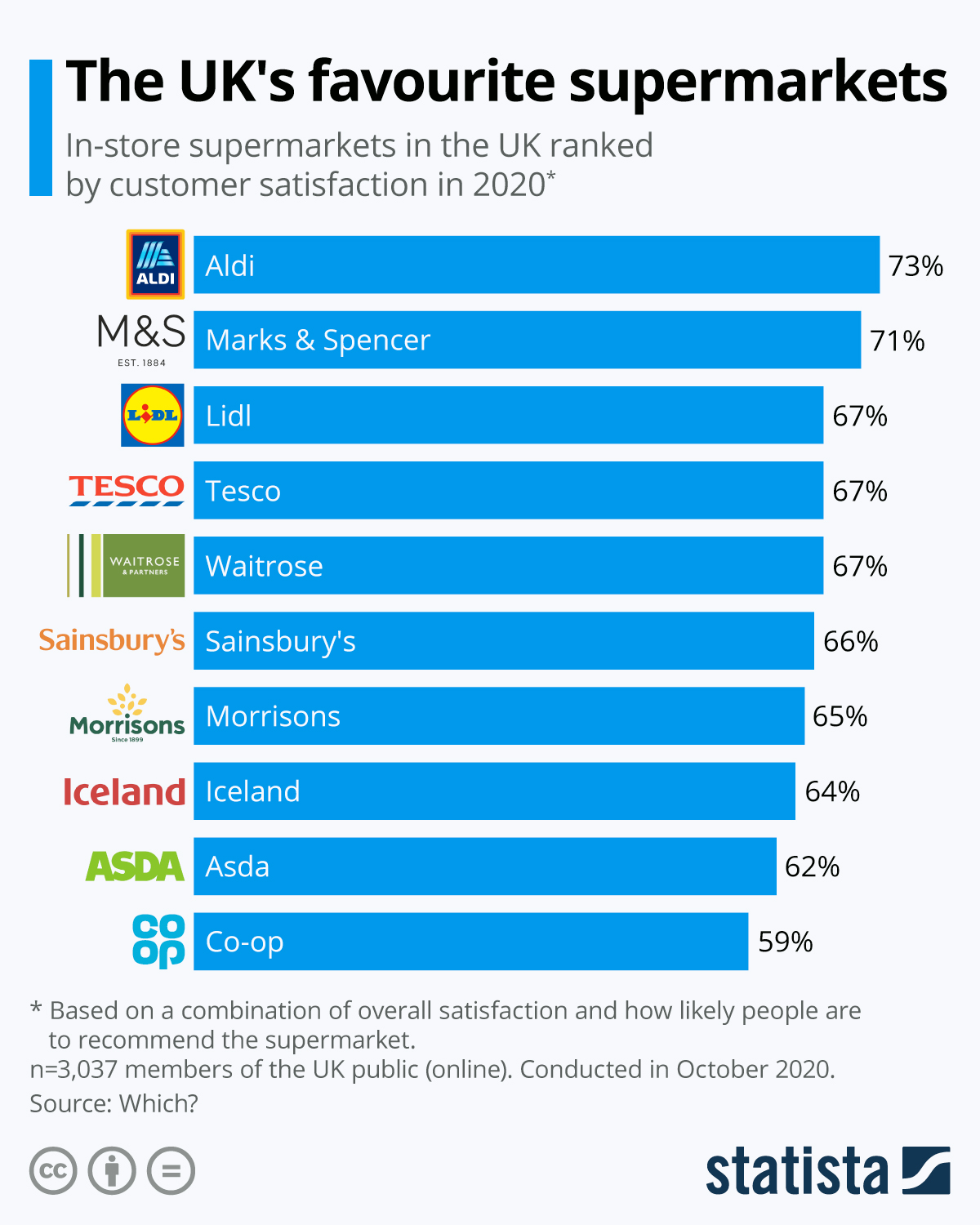

Revealed Top And Bottom Uk Diy Retailers In 2024

Apr 23, 2025

Revealed Top And Bottom Uk Diy Retailers In 2024

Apr 23, 2025 -

Analysis Trumps Call For Powells Termination And Its Implications

Apr 23, 2025

Analysis Trumps Call For Powells Termination And Its Implications

Apr 23, 2025 -

Cincinnati Reds The Story Behind Their Unusual Losing Streak

Apr 23, 2025

Cincinnati Reds The Story Behind Their Unusual Losing Streak

Apr 23, 2025