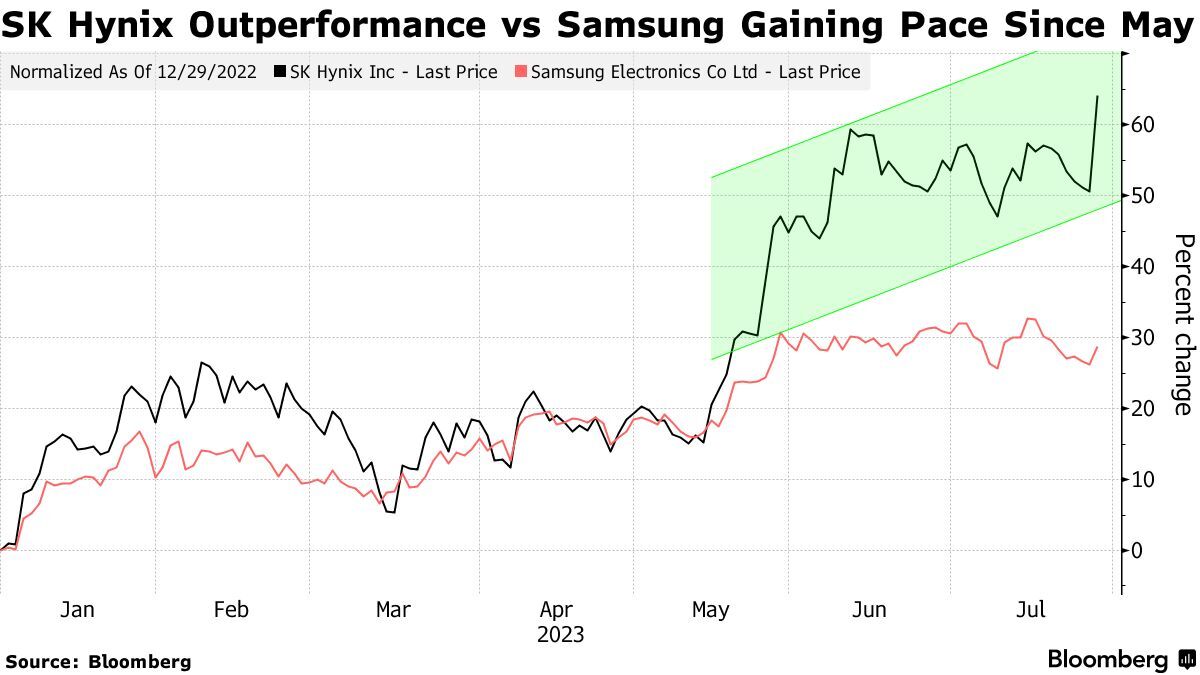

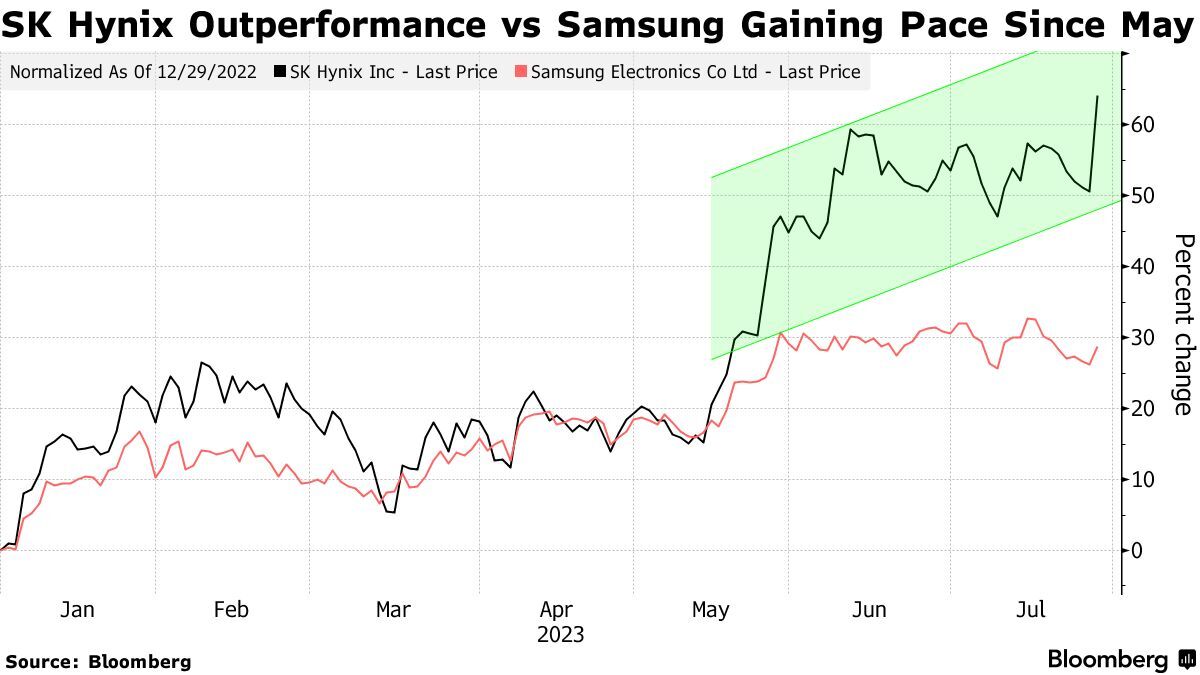

AI Boost Propels SK Hynix To Top DRAM Manufacturer, Overtaking Samsung

Table of Contents

SK Hynix's AI-Driven Manufacturing Efficiency

SK Hynix's ascent to the top is not accidental; it's the result of a strategic and aggressive implementation of AI across its manufacturing processes. This AI-driven approach has significantly boosted efficiency, leading to higher yields and lower costs. The company has focused on several key areas:

-

Implementation of AI-powered predictive maintenance systems: By leveraging AI algorithms to analyze sensor data from its manufacturing equipment, SK Hynix has minimized downtime caused by unexpected failures. This predictive maintenance approach allows for proactive repairs, preventing costly production halts. Reports suggest a significant reduction in unplanned downtime, resulting in a considerable boost in overall productivity.

-

Utilizing AI algorithms for real-time process optimization: AI algorithms continuously monitor and adjust various parameters in the DRAM manufacturing process, ensuring optimal conditions for chip production. This real-time optimization has led to a measurable increase in yield – the percentage of successfully produced chips – compared to traditional methods.

-

AI-driven quality control systems drastically reducing defect rates: AI-powered inspection systems identify and classify defects with far greater accuracy and speed than human inspectors. This has significantly reduced the number of faulty DRAM chips, improving overall product quality and lowering waste.

-

Automated processes reducing reliance on manual labor and improving precision: AI has enabled the automation of several labor-intensive tasks within the manufacturing process. This has not only increased production speed but also significantly improved precision, further contributing to higher yields and reduced defects. The level of automation achieved by SK Hynix is a major factor in their competitive edge.

The integration of AI across all these stages has resulted in a demonstrable improvement in manufacturing efficiency. While precise figures are often kept confidential by companies in this highly competitive sector, industry analysts have noted a significant increase in SK Hynix's production output and a reduction in production costs.

Samsung's Challenges and Market Dynamics

While SK Hynix’s advancements are undeniable, Samsung's slight decline in market share is a complex issue, influenced by several factors:

-

Supply chain disruptions: The global semiconductor industry has faced significant challenges in recent years, including supply chain disruptions caused by geopolitical events and the ongoing pandemic. While both companies have been impacted, Samsung's response may have been less effective in mitigating these challenges.

-

Market demand fluctuations for DRAM: The demand for DRAM fluctuates based on various factors, including the overall economic climate and the growth of specific industries (like data centers and smartphones). Shifts in market demand can significantly impact the fortunes of manufacturers.

-

Internal factors impacting Samsung's production or market strategy: Internal factors, such as strategic decisions regarding investments in research and development, capacity expansion, or pricing strategies, could also have contributed to Samsung's relative decline. Industry experts suggest that Samsung might need to re-evaluate its strategy to regain its leading position.

The Impact of AI on the Semiconductor Industry

The SK Hynix success story is a powerful illustration of AI's transformative potential within the semiconductor industry. Its impact extends far beyond simply increasing production efficiency:

-

AI is reshaping semiconductor manufacturing: The adoption of AI is becoming increasingly widespread across semiconductor manufacturing plants globally, leading to significant efficiency gains and cost reductions.

-

AI is transforming other aspects of the semiconductor industry: AI is not only revolutionizing manufacturing but is also playing an increasingly important role in other areas, such as chip design, research and development, and testing.

-

The future potential of AI in driving further innovation and efficiency: AI is poised to drive even greater innovation and efficiency within the semiconductor industry in the coming years, leading to the development of more powerful and energy-efficient chips. We can expect to see continued investment in AI technologies across the board.

Long-term implications for DRAM pricing and availability

The shift in market leadership from Samsung to SK Hynix is likely to have significant long-term implications for DRAM pricing and availability:

-

Potential impact on DRAM pricing: Increased production efficiency from AI may lead to lower production costs, potentially translating into lower prices for DRAM chips. However, the interplay of supply and demand will ultimately determine pricing.

-

Impact on the availability of DRAM chips: Increased production capacity at SK Hynix might ease any potential shortages of DRAM chips. However, other factors, such as overall market demand, could influence availability.

-

Future market fluctuations: The semiconductor market is inherently volatile, subject to frequent fluctuations in supply and demand. The current shift in market leadership will likely lead to continued market instability in the short term, but eventually, a new equilibrium will emerge.

Conclusion

SK Hynix's rise to the top of the DRAM manufacturer rankings is a testament to the power of AI-driven innovation. By strategically integrating AI into its manufacturing processes, SK Hynix has achieved significant improvements in efficiency, yield, and quality control. While Samsung faces challenges related to market dynamics and internal strategies, the broader impact is the clear demonstration of AI's transformative power within the semiconductor industry. This shift underscores the importance of technological advancement and the strategic implementation of AI in maintaining a competitive edge. Stay informed on the evolving dynamics of the DRAM market and the continuing influence of AI on SK Hynix, Samsung, and the broader semiconductor industry. Follow [Your Website/Source] for the latest updates on AI advancements and their impact on the memory chip landscape.

Featured Posts

-

Why This Startup Airline Uses Deportation Flights

Apr 24, 2025

Why This Startup Airline Uses Deportation Flights

Apr 24, 2025 -

Nba

Apr 24, 2025

Nba

Apr 24, 2025 -

Chalet Girl Life Honest Insights Into A High Demand Winter Job

Apr 24, 2025

Chalet Girl Life Honest Insights Into A High Demand Winter Job

Apr 24, 2025 -

Microsoft Activision Deal Ftcs Appeal And What It Means

Apr 24, 2025

Microsoft Activision Deal Ftcs Appeal And What It Means

Apr 24, 2025 -

Cantors Potential 3 Billion Crypto Spac Deal With Tether And Soft Bank

Apr 24, 2025

Cantors Potential 3 Billion Crypto Spac Deal With Tether And Soft Bank

Apr 24, 2025